OP 93. A Benchtop Model for Comparison of Implant Abrasiveness

T. Ebner, A Throm, D. Jermine, E. Contini, D. Bronson

Chair(s): Norbert Németh, Ivo Post & Thomas Hubert

11:30 - 11:40h

at Buda Room (B)

Categories: Innovative Surgical Research, Novel Techniques and Product, Oral Session

Session: Oral Session X - Innovative Surgical Research

Background

Surgical staplers are commonly used surgical devices which enable surgeons to simultaneously cut and staple tissue. In some cases staple line reinforcement material, or buttress, may be added to increase compression and reinforce fragile tissue. A benchtop test was developed to model the use of buttress and investigate abrasive effects of dynamic, cyclical contact between buttressed staple lines and surrounding tissue with quantitative and objective metrics.

Material and Methods

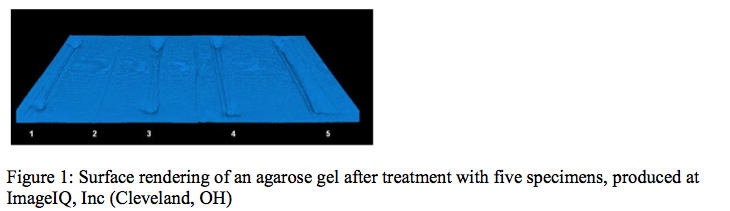

Staple line wedges were formed in synthetic media using various buttress products and a custom abrasion substrate was fabricated by polymerizing agarose gel with aluminum oxide in suspension. An electromechanical system was used to cycle wedges against the gels in a controlled repeatable manner. A high resolution 3D laser scanner was then used to measure the volume of each defect, allowing allow for objective comparisons between buttress groups.

Result

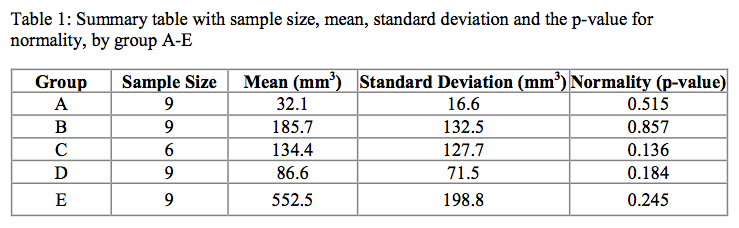

Mean defect volume was 32.1, 185.7, 134.4, 86.6, and 552.5 mm^3 for Groups A, B, C, D, and E, respectively. All groups followed a normal distribution (p-value > 0.05). Based on the 95% Bonferroni confidence intervals, there were statistically significant differences between some of the groups.

See Figure 1: Surface rendering of an agarose gel after treatment with five specimens, produced at ImageIQ, Inc (Cleveland, OH)

See Table 1: Summary table with sample size, mean, standard deviation and the p-value for normality, by group A-E

Conclusion

Initial testing showed feasibility of the method to compare abrasiveness between devices with slight differences in composition. This is a new tool for product development, from benchmarking the performance of predicate products to evaluating new product concepts. Ultimately this method may be adapted to model the application of other devices to evaluate potential abrasiveness with objective and quantitative metrics.